X-ray technology is a valuable tool for the conservators at Jamestown. Often times artifacts excavated around James Fort are covered in so much rust that they resemble Cheetos or fried chicken. X-raying these objects serves two purposes; it allows the conservators to identify objects and also shows them the artifact’s weak points so that they can take special care when conserving those areas.

Identifying an artifact via X-ray is useful to the team so that they can decide whether it’s worth the time and money to conserve the object. If it’s a nail, the like of which thousands have been excavated since the fort was found in 1994, it’s unlikely the team will make any changes to the object after cataloging and storing it. But if an artifact is selected for conservation, X-ray imagery excels at revealing the dense — and less dense — sections of the objects. This is instructive for the team as they will use this information to help formulate their conservation plan. For metal objects, the oxidation (rusting) process causes loss of the original metal, sometimes so much so that removing the rust would cause irreparable harm to the artifact. In other instances the density is uneven, with parts of the artifact having enough original metal to conserve the object but other, less dense sections requiring extra care, different methodologies, or the lack of conservation altogether.

Jamestown’s X-ray machine was installed in the conservation lab in 2008 and has been an invaluable tool to the team since then. Much of the setup is still viable, but the X-ray panel has gone downhill after years of being battered by electomagnetic radiation from the X-ray source just above it. The images produced by the machine now typically show just the object’s outline and little to no detail in its interior. They are nearly useless in this state and so the decision was made to research and replace part or all of the X-ray machine.

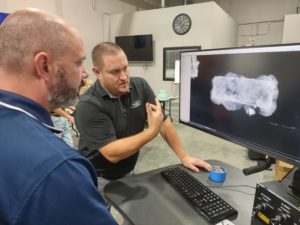

Michael Lavin, Director of Collections and Conservation, Dr. Chris Wilkins, Archaeological Conservator, and Benjamin Knowles, Senior Web/IT Specialist, were invited by Matt Gormley of Pinnacle X-Ray Solutions to visit their facility in Suwanee, Georgia to explore the different options Pinnacle could offer to get Jamestown’s X-ray machine back on its feet. Michael and Chris selected a number of artifacts to bring with them to test using Pinnacle’s equipment, some of which were rendered unidentifiable by their heavy coat of rust.

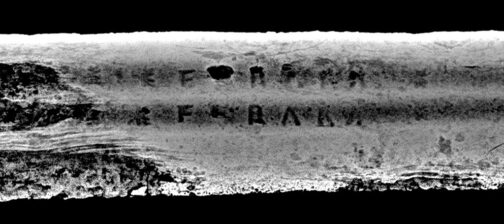

Matt gave the Jamestown Rediscovery team a tour of their manufacturing facility and then the team prepared several artifacts for the X-ray machines. Chain armor, a coin-shaped object, a sword pommel, jack-of-plate armor, and a file were among the items X-rayed. The chain armor was scanned using Micro-CT, a technology that provides a 360-degree X-ray view of an object. Individual rings of the heavily-rusted armor were made readily visible by the scan. The sword pommel’s identity was confirmed as was a series of buckles concreted together by rust. A coin-like object was the final object X-rayed. It was unknown if it was a coin, a jetton, or something else, its identity shrouded by corrosion. But the X-ray cut through the rust and revealed it to be a King’s Touch Token, probably distributed to commemorate the coronation of James I of England in 1603.

Pinnacle X-Ray Solutions is now preparing a few options that are compatible with Jamestown Rediscovery’s current X-ray cabinet and X-ray source that would reenable Jamestown’s X-ray capabilities. We are also researching ways to integrate the X-ray process with our collections database such that X-raying the artifact would automatically populate certain fields in our collections database. We are grateful to Matt and the rest of the team at Pinnacle X-Ray Solutions for spending the day with us and allowing us to test our artifacts on their systems. Their willingness to offer a custom solution that uses the working parts of our existing setup will be a life saver for our budget and lessen the learning curve with the new hardware.

Related Images

- Pinnacle’s Cameron Ward and Jake Rickter prepare a stage for the chain armor as Conservator Dr. Chris Wilkins looks on.

- The staged chain armor is ready for its X-ray.

- Pinnacle’s Jake Rickter shares an X-ray of chain armor with Conservator Dr. Chris Wilkins.

- Pinnacle’s Jake Rickter reviews the CT scan of the chain armor.

- Pinnacle’s Justin Rickter demonstrates a robotically-assisted X-ray machine being manufactured by Pinnacle X-Ray Solutions.

- Pinnacle’s Matt Gormley and Cameron Ward discuss staging an artifact for the X-ray machine.

- Director of Collections & Conservation Michael Lavin holds a rusted King’s Touch Token next to an X-ray of the object.