Reaching into the muck, the words “Is it a snaphaunce, a matchlock? It’s mostly brass covered in mud!” rang out amongst the crowd of local, national and international visitors, cameras, and microphones on site that day in 2006. A pistol had been recovered from the bottom of the 1611 well at Jamestown from which other fabulous artifacts had been removed including a halberd, a pike, and a shipping tag with the destination of “Yamestowne” stamped into the surface. The pistol was an amazing find and continued investigation would reveal it to be composed of a mix of materials including a copper alloy barrel, an iron Roman lock plate and machinery, and a wood stock. Further analysis including the use of X-radiographs (X-rays) and probes revealed the pistol to be double-loaded, with two large lead shot positioned in front of a charge of waterlogged black powder.

The pistol was in fairly good condition despite resting in mud at the bottom of the well for nearly 400 years. Certainly the anaerobic environment had a positive effect on the pistol by limiting access to oxygen, which is responsible for much degradation. While there was corrosion on the iron bits, the barrel was nearly brassy, and the wood, while waterlogged, was intact. Subsequent exposure to oxygen in the air would turn the copper alloy barrel green and the iron lock plate and machinery slightly more red due to corrosion of the metal components, yet this was expected. The wood, however, was in great condition and would remain so as long as the pistol was immersed in water. But it could not remain submerged forever. It would have to be dried not only to arrest the corrosion of the metal components, but to enable the pistol to be placed in storage, put on exhibit, and to be handled by researchers. The goals of the pistol conservation were set: to remove deposits on the surface of the pistol, to stop the active corrosion of the metal components, and to dry the waterlogged wood components of the pistol while retaining its shape and color.

The conservation of the pistol required several steps to reach these goals and to ensure the pistol’s future structural integrity. Firstly, the pistol was cleaned, having just been recovered from the mud at the bottom of a well. A crust composed of cemented iron corrosion and other materials, which were covering the lock plate and portions of the wood stock, were removed using an air scribe (similar to a small handheld jackhammer) to reveal the pistol surface. The two lead shot in the barrel were extracted by unplugging the muzzle and removing any additional corrosion in the barrel that was impeding the removal of the shot. This was easier than previously thought and the two shot merely rolled out the muzzle after a little cleaning. Currently, we are preparing to remove iron staining from the wood to reveal the color and to limit potential problems that could occur later if the staining were to be retained. Afterwards, polyethylene glycol (PEG) will be used to bulk the wood, this being followed by freeze-drying to remove the water. Without bulking the wood cell structure would collapse leading to distortion of the wood stock and handle in the form of shrinkage, cracking, and fragmentation.

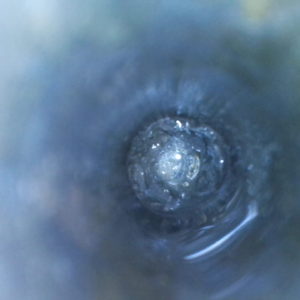

As mentioned above, we found black powder in the barrel. Black powder is composed of three main ingredients: charcoal, potassium nitrate, and sulfur. Sulfur can cause problems in the wood years after conservation is completed, not only by producing a yellow bloom on the surface but by potentially combining with humidity in the air to produce sulfuric acid which will attack the wood and metal parts. Therefore, sulfur needs to be removed from the pistol. Much of the powder has been removed (and mostly collected) by mechanically breaking it up with a long wood skewer. In this video, an endoscope is being used to determine if there is sulfur-containing powder remaining in the barrel. From the darkness what at first appears to be a round shot within the barrel is actually the concave breech plug (i.e. the back of the barrel). The darker areas immediately surrounding this is caked black powder remaining within the barrel. Sometimes conservation can seem like a crime scene investigation and two additional sites of interest were noted while moving the endoscope down the barrel. A whitish residue on one side of the barrel interior most likely represents where the lead shot rested for the last four centuries. Lead corrosion is white and some of this corrosion material has been deposited on the barrel interior in the vicinity of the shot. Slightly more difficult to see is a red staining between the white residue and the breech plug. This is iron staining but how did that make its way into the interior of the copper alloy barrel when the muzzle was plugged with mud? It could not be the shot which is composed of lead and no other objects were identified within the barrel. The source had to be from outside of the barrel. The only other possibility is that the reddish stain is caused by iron salts from the lock plate and machinery entering through the touch hole, the hole that provides ignition from the flash pan to the black powder charge within the barrel. Mystery solved.

Removal of the remaining powder with the barrel will enable us to continue with the conservation of the pistol. This treatment will continue for the next several months and will hopefully be completed by December 2021. We will continue to post on the progress of the pistol conservation.

related images

- Interior view of the pistol’s breech plug