Encountering Sulfate Reducing Bacteria at Jamestown

April 12, 2024. Janene Johnston, Associate Curator, and Dr. Chris Wilkins, Senior Conservator.

Archaeologists recovered a trove of interesting artifacts during excavations of the Governor’s well in the fall of 2023. Amongst these were several large iron objects including a billhook, three swords, a sawblade, and several pieces of armor. One particularly exciting find was a fairly intact rapier, comprised of the pommel, hilt, and a portion of the blade. In addition to this largely intact portion of the rapier, nine small fragments of the hilt were recovered throughout the well.

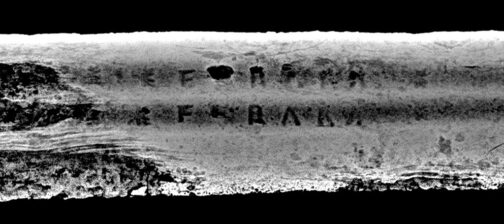

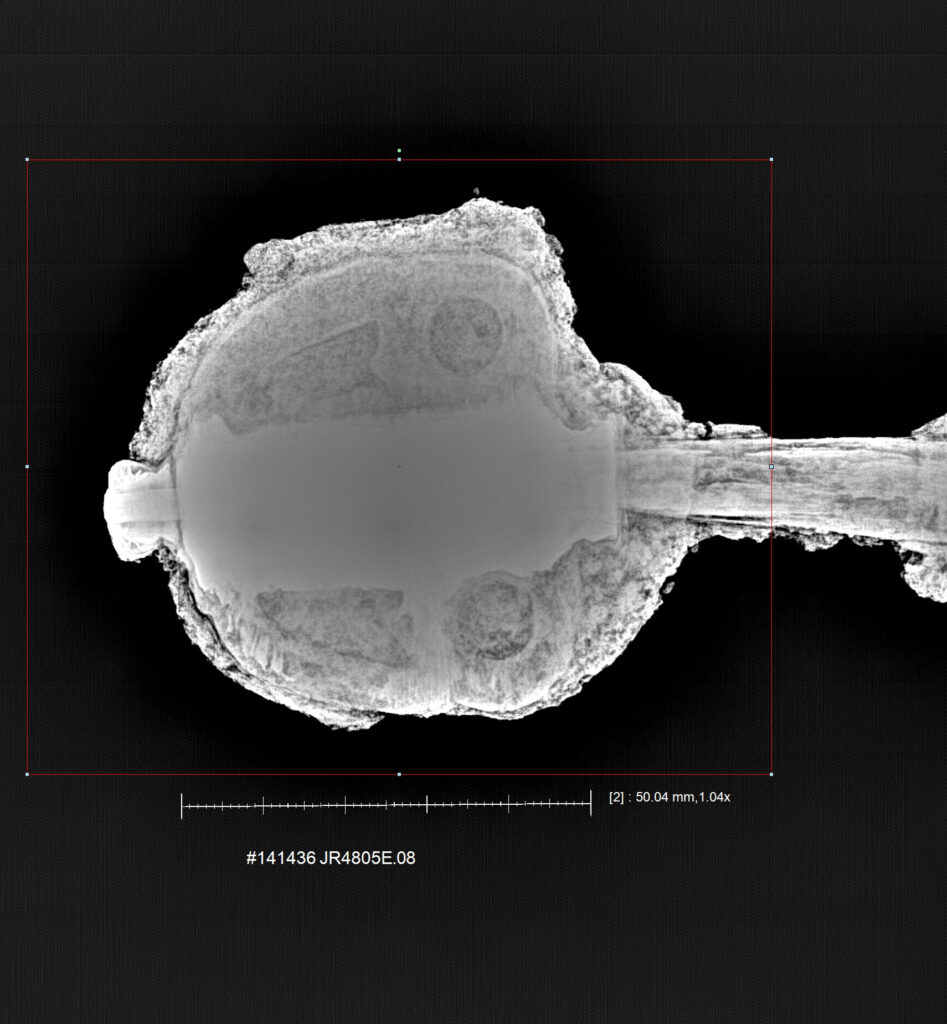

Though the rapier was heavily corroded, an edge of the original metal of the pommel was visible. The shape of the visible metal suggested the pommel was not solid, like most other sword pommels in the Jamestown Rediscovery artifact collection. The curatorial team suspected this could be one-of-a-kind for us, making the artifact even more intriguing. X-rays (below) taken by Jamestown’s conservators confirmed our suspicions that the pommel was hollow, and trefoliate (meaning resembles a trefoil) in silhouette.

Combined with the distinctive style of the quillons (the two arms forming the crossguard), it is likely that this is a Spanish rapier made during the mid-16th to mid-17th century. A similar Spanish rapier dated ca. 1575 is in the Victoria and Albert Museum collection.

We always anxiously await the end of the conservation process, as seeing the artifacts stabilized and expertly cleaned is an exciting reveal. Additionally, once conservation is complete for this rapier, we’d like to see if any of the additional hilt fragments recovered from the well can be reunited with the intact portions, and we would like to pursue further research on the artifact. However, the iron artifacts from the Governor’s Well are behaving quite differently than other iron excavated from the site, and the conservation process is taking a little longer than expected, including for this amazingly intact rapier.

Conserving the Well’s Iron:

Excavated iron from terrestrial Jamestown contexts generally looks like a bulbous mixture of sand, brick, and iron, cemented together with iron corrosion of varying shades of reds, oranges and browns. Exposed core metal appears gray to black, and the smell of the iron is generally the smell of the surrounding soils. Iron materials recovered below the waterline in well features at Jamestown typically have thinner corrosion crust and no distinctive smell. Iron artifacts recovered from waterlogged contexts like the well are initially kept in water to remove the potential of aggressive localized spot corrosion. However, due to the number of iron artifacts coming into the lab as the excavation was ongoing, collections staff worked together to start cleaning the artifacts as they were brought in, using toothbrushes and wooden tools to clear away excess mud and dirt.

As the artifacts recovered from the Governor’s Well were being cleaned, it was noted that the iron objects had a thin, black, almost oily coating and an indescribable industrial-like smell that was lacking in the well water itself. We took note of this, but proceeded with our normal procedures. After cleaning, the artifacts were dabbed dry in preparation for cataloging and x-radiography before they continued through the conservation process. During air abrasion, the next stage of conservation in which corrosion is removed, conservators noticed that the iron corrosion was more dense than usually encountered on iron from Jamestown. Removing this tough corrosion product means that the air abrasion process for each iron artifact took longer than normal.

Part of the conservation process for iron is the removal of chloride salts, which are a catalyst for continued corrosion. This process, called desalination, involves the immersion of the iron into a series of highly alkaline aqueous baths of sodium hydroxide, which stops the corrosion of iron and allows the salts to disperse into the surrounding liquid. After these baths, residual sodium hydroxide is washed out and the iron is carefully dried. During the desalination process of iron artifacts from the Governor’s Well, including the rapier, a moderately strong sulfur smell was apparent, and a new reddish-orange splotchy localized color on the surface was noted after drying. These unusual characteristics, combined with the strange smell and oil-like sheen of the iron as it was cleaned in the lab, were all indications of sulfate reducing bacteria (SRBs), a category of bacteria that requires an anoxic (lacking oxygen) environment to survive.

The Bacteria:

These phenomena could be caused by a number of factors that are unique to this particular well or possibly even from the prolonged effects of sea level rise that the island is facing. Though tests have proved inconclusive on the origin of these bacteria, they are producing hydrogen sulfide which is reacting with the iron. Characteristics such as the black biofilm, increased density of the corrosion crust, and sulfur blooms are all a direct result of the presence of these SRBs. Sodium hydroxide baths are known to remove chloride salts and are suggested within the conservation literature as an appropriate method for the removal of sulfide salts. Thus, our desalination process to remove chlorides is working because the smell of sulfur is very evident. As a result, we are extending the length of time an artifact remains in the sodium hydroxide baths until we can no longer detect the presence of sulfur and sulfur compounds in the aqueous solution.

The issue of sulfur and artifacts in anaerobic environments can be tricky depending on the material. For iron, it seems straightforward in the sense that it is readily detectable once you know what you are looking at. This also extends to other metals including aluminum, titanium, zinc, nickel, and copper alloy. Beyond metals, waterlogged wood can become partly infused with pyrite, a sulfur compound. Typically a concern for wood recovered from saltwater marine environments, evidence of pyrite infusion does not become visual until the formation of sulfur blooms years after it was conserved.

Moving Forward:

Having noted the strange characteristics of the iron recovered from the Governor’s Well, and having conducted the research on how to best move forward, Jamestown’s conservators are now armed with the information required to mitigate the damage before it becomes too severe for all material types within our collections. We are also prepared to deal with newly recovered artifacts in the future as they are excavated from anaerobic environments should they pose similar problems. The rapier and its hilt fragments are still undergoing their alkaline baths. Conservators will continue to carefully monitor it and other iron artifacts as they progress through the process. We will be sure to post an update to our social media platforms when the rapier is fully conserved.