Conservation of a large early 17th Century Case Bottle

Jackie Bucklew, Conservation Intern

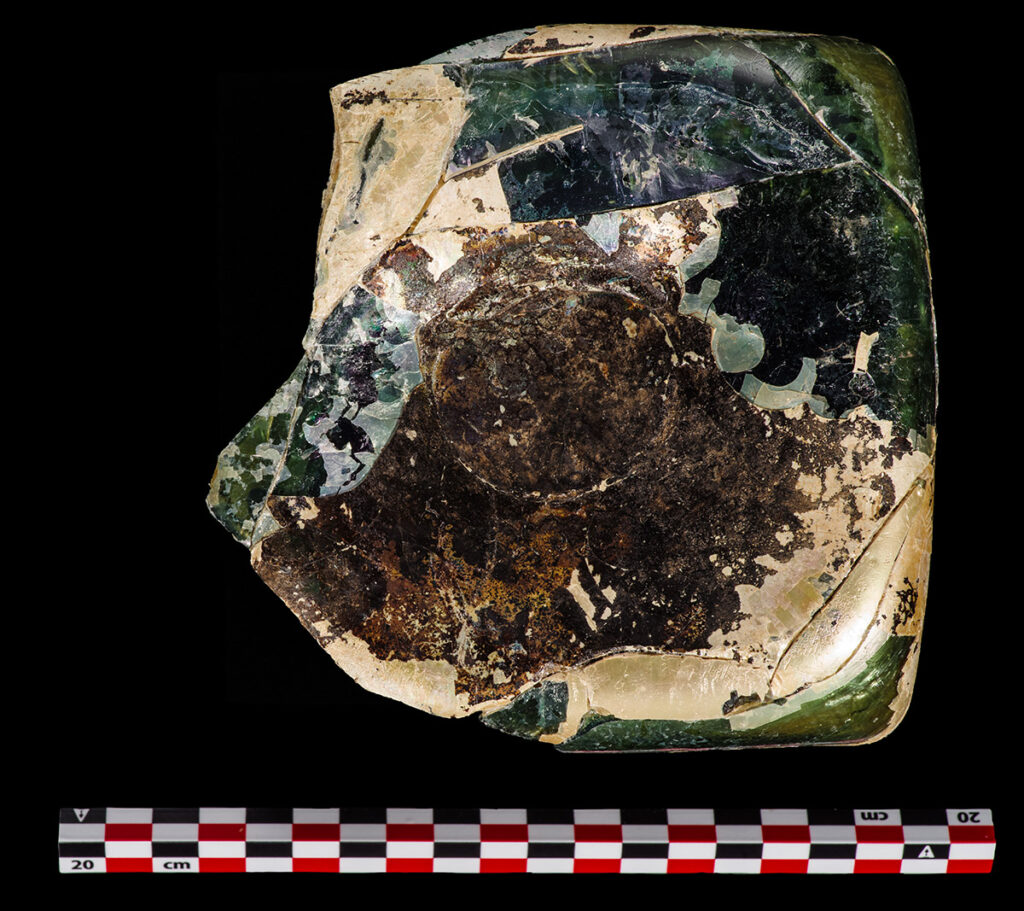

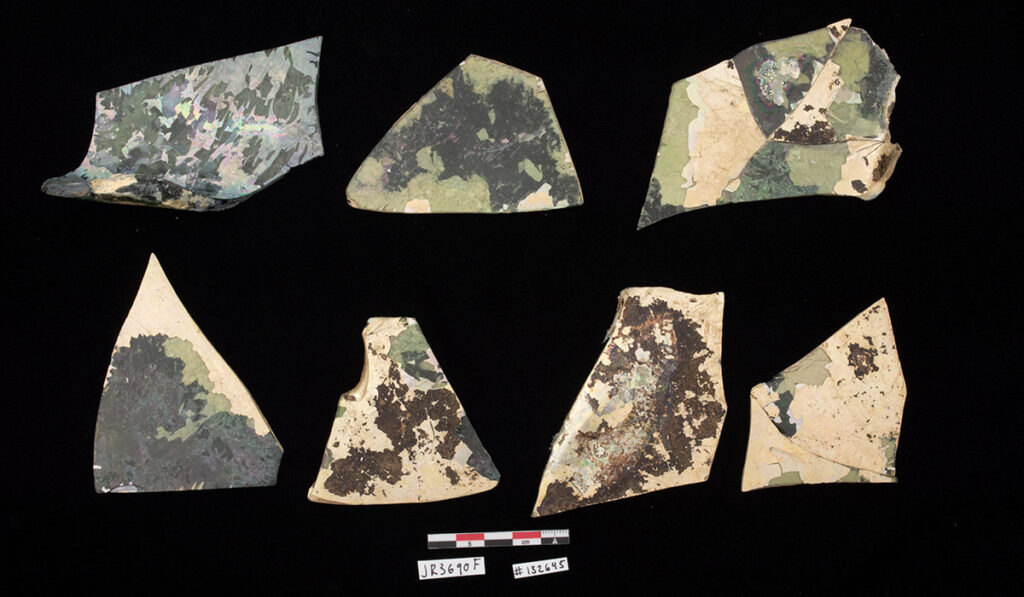

In 2014 archaeologists Mary Anna Hartley and Danny Schmidt excavated fragments of a case bottle found in a fort period cellar feature of the northeast corner of James Fort’s 1608 addition. (Fig. 1) The case bottle had been partially mended by conservator Katie Cornelli, joining enough shards to establish the dimensions. After a few years in the collection, it was due to be reassessed. This included updating the description, noting the condition, taking photographs and measurements. Additionally, looking into the history of this settlement, some 17th century fort renovations had potential to spread shards of this vessel across the site. This prompted a search in the archive which produced additional shards that had not previously been associated with this bottle. At this point it was decided this bottle would be given further conservation treatment.

The condition of the glass showed it had undergone chemical degradation while in the ground. This process involves ground water molecules disrupting the silica-oxygen bonds by leeching the glass alkali stabilizers (i.e. sodium and potassium) used in glass making. This caused the formation of gel layers (glass delamination) and an uneven refractive index resulting in an iridescent appearance, and eventually in a loss of glass.

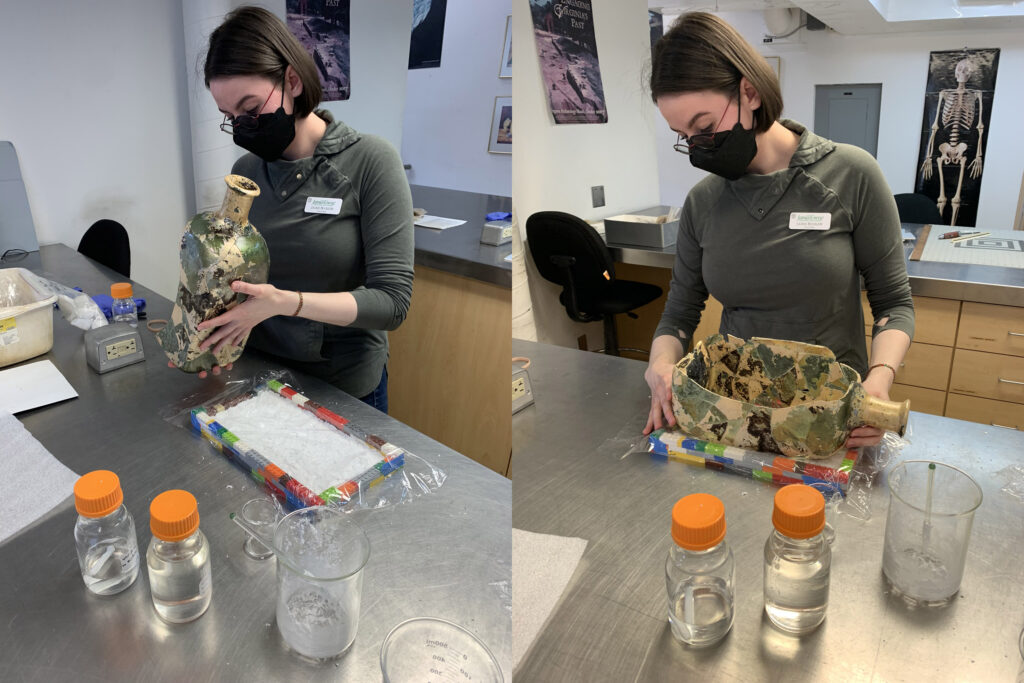

The goal was to prevent the continued delamination of the gel layers, which was achieved using 8% B-72 (w/v in acetone). B-72 is a synthetic acrylic resin used as a coating, but also as a consolidant, or an adhesive at higher concentrations. At 8% it’s quite runny, but it produces a thin layer that can be drawn into tiny crevices through capillary action, thereby consolidating the thin gel layers of delaminating glass. Once each of the total 200+ shards were coated, and had about 12 hours to set, it was time to start piecing it back together. Using a concentration of 20-40% (w/v in acetone), B-72 was applied by brush to both mending edges, thick enough to adhere but thin enough as to not cause a gap that could be problematic as the bottle is built up over time. After a few minutes holding the piece in place, the newly mended shards were supported in a sand box with cling film barrier and left to set overnight.

Adhering glass shards is more difficult than adhering ceramic sherds; the break is usually quite smooth and when joining, it seldom ‘grips’ like ceramics. With the smooth break edges the mends tend to drift if not perfectly supported, causing the joins to be close but ultimately needed adjustments. To do that without completely removing the mend, cotton wool is rolled into a cylinder shape, dipped in acetone and placed directly over the join. After a few minutes the mend is adjustable again. If needed, leaving the dampened cotton wool a bit longer allows the shard to be completely removed. When a shard is removed, a cotton bud and acetone are used to clean the residual adhesive off the break edge. Since B-72 was used both as consolidant and adhesive, extra care was taken to ensure the consolidant coating was not affected. If a shard showed signs of flaking after being adjusted or removed, a new layer of 8% B-72 was applied.

After joining all 132 shards, this bottle is easily the largest in the collection. It measures 37 cm tall, 14.5 cm wide and would have held approximately 193 fluid ounces or 1.5 gallons. For comparison, an average case bottle of this period holds approximately 45 fluid ounces and measures around 20 cm tall and 8 cm wide.

With the bottle as close to completion as our archaeologists could provide, it was apparent that it could not be stored in its assigned drawer standing upright. Generally, it’s best to keep objects in their originally intended orientation. When this is not possible supports and mounts are the next best option. A support of glass microspheres and B-72 was made allowing the bottle to be stored horizontally. To make this support, 3M glass microspheres were mixed with 40% B-72 (w/v in acetone) to produce a crumbly putty consistency. The bottle was gently pressed into the material to form a contoured support. Having the bottle fully supported reduces the risk of pressure points or damage to the individual shards and the bottle as a whole.

After the solvent evaporated, the support remains strong and lightweight. As for supporting the neck, a few layers of ethafoam were added to the base. The bottle will be housed with the rest of the glass collection in a temperature and humidity-controlled environment to help preserve these artifacts for as long as possible.

This project, though daunting, has ultimately been rewarding. When I began this project my mentor, Dr. Chris Wilkins told me, “in conservation, this will probably be the hardest thing you ever do.” Maybe trying to keep my expectations at bay, but also giving me an awareness of the estimated timeframe. Not only is the task of finding mends challenging and time consuming but also only being able to adhere 1-3 shards a day and waiting overnight for those pieces to set. A few times, this would be nearing completion, only to find a gap near the top, indicating a join was not perfect. This would require me to take down mends or make adjustments until the pieces could fit. Now with a renewed sense of patience, I will take this knowledge and experience onto my next conservation project.