The footprint of the original James Fort is a military site, so 21 years of archaeology has uncovered a lot of iron tools, armor, and weapons. Wintertime becomes a crucial window to conserve those iron artifacts while there is no active excavation happening on the site.

The footprint of the original James Fort is a military site, so 21 years of archaeology has uncovered a lot of iron tools, armor, and weapons. Wintertime becomes a crucial window to conserve those iron artifacts while there is no active excavation happening on the site.

Many of the lumps of rust come into the Rediscovery Center laboratory looking like pieces of fried chicken. The iron artifacts are not washed because chlorinated tap water mixing with oxygen and water vapor in the air will cause MORE rust.

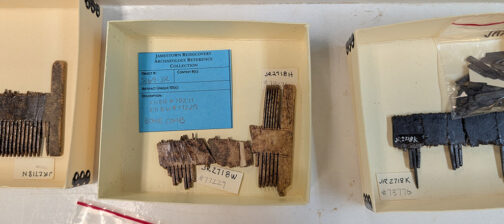

So after the rust-covered artifact is cataloged and assigned a unique identification number, it gets an x-ray. The x-ray is an important tool because often the archaeologists cannot easily identify an object in the field because so much rust has accumulated on the object. Conservator Dan Gamble and staff archaeologist Don Warmke do most of the x-ray work.

The project takes an average of 350 x-rays a year, and there were almost 400 in 2012. The conservators used to take artifacts to a NASA Langley lab in Hampton or to Colonial Williamsburg’s lab for this non-destructive diagnostic tool. Then Jamestown Rediscovery was awarded a grant from the Institute of Museum and Library Services that delivered a digital x-ray machine to the project’s own lab in 2009. Since then the Jamestown team has taken x-rays of more than 2,000 non-nail iron objects from the James Fort-period features. Having the equipment at hand allows for a richer database about many artifacts.

Sometimes the x-ray can even show a “maker’s mark” on an iron tool, which helps date and locate the origin of the tool. On the x-ray picture, the areas that show up white are more dense, the black areas are less dense.

If the object is found to consist of solid metal with no weak spots, it is put into a tub of water with three percent sodium carbonate for the process of electrolytic reduction. This process reverses the flow of electrons, causing the rust to drop off. Warmke manages this process for objects such as cannonballs, hoe blades, cooking pots, axes, or other heavy tools, which tend to survive relatively intact.

“It’s essentially a tank of water and a bar going across the top which is attached to the iron objects that have come out of the field,” Warmke said. “We are using these wire leads, running an electric current through these artifacts. The gross corrosion is basically being repelled and put into the water here.”

The time in the solution varies for each object, but objects are in the electrolysis tank for at least a month.

If the x-rays show there’s not enough iron beneath the rust, the artifact is air abraded with a very fine aluminum oxide powder. An air abrader is a hand-held tool similar in form to a pencil that propels a fine powder at an object through the use of pressurized air. Though time-consuming, the tool has a fine tip and enables a high level of precision, perfect for objects that can’t withstand a brute-force approach to rust removal.

Gamble and Warmke do most of the air abrasion now. It’s like a mini-sandblaster to blow away the rust and takes a lot of skill because you don’t want to take away any information from the artifact. It’s like the doctor’s oath. The first rule is: do no harm. A sword hilts take three to four days of abrasion work, for example.

After objects are done with the electrolysis or the abrasion process, they spend three or four months soaking in a de-ionized solution with less than four parts per million of soluble chlorides, which leaches even more chlorides out of the artifacts.

Then there is time in a vacuum chamber with silica gel to dry out the artifact. After all this cleaning and stabilization, a conservator takes the flash rust off the object with some more air abrasion and coats the artifact with acrylic to protect it before going on display in the Archaearium or into storage in the dry room of the Vault at the Rediscovery Center.

related images

- The head of a bill (type of polearm weapon)

- A spade nosing

- Bill hook and shovel spade from the pit

- Senior Conservator Michael Lavin and Archaeologist Don Warmke use air abrasion to remove rust from metal artifacts found in the well